Products

Omiga Programmable Servo Controller

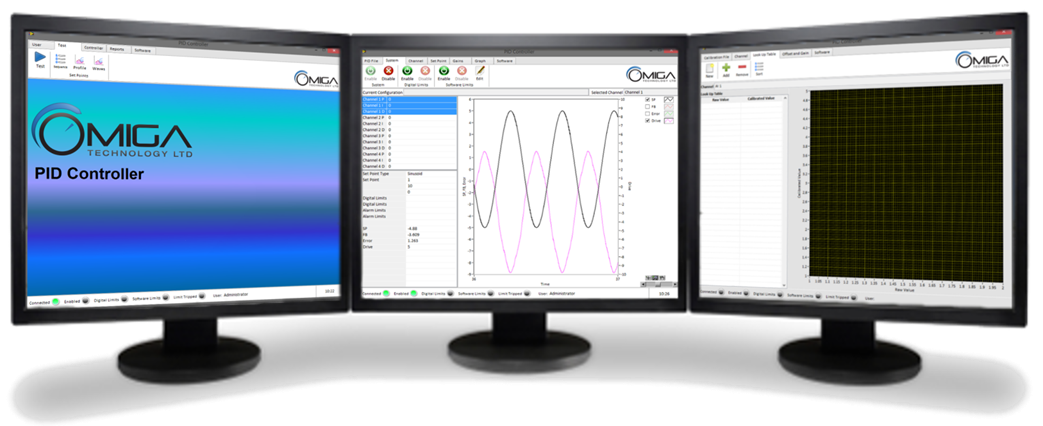

Setup | Create | Tune | Test | Log | Analyse | Report

Omiga Technology’s fully configurable servo test controller. This multipurpose system is designed to be highly configurable in both the software and the hardware in order to meet a wide range of requirements for hydraulic servo control systems.

Proven Omiga servo control methodologies

-

Flexible | Configurable

-

Local touchscreen display

-

Intuitive user interface

-

Linkable via ethernet

-

Local or PC control

-

NI cRIO Technology

The controller incorporates proven PID and Cascaded Incremental technology to provide a configurable test controller for servo hydraulic and generic test systems that require synchronized multichannel control. The touch screen display allows standalone operation with USB interface for file transfer and network connection for operation via the PC application. Configurable analogue inputs allow additional channels for logging, digital I/O enables solenoids, limit switches to be added and multiple units linked for larger systems via ethernet.

The powerful software provides complex output profile and test sequence compilation with active profile alarm features. The combination of configurable hardware and powerful software interface make it an indispensable tool for a wide range of test requirements.

Standard Features

• 19” Rack Mountable Enclosure

• 4U (176mm) Enclosure Height

• External Depth: 420mm (behind ears); 540mm free space recommended

• External Height: 176mm (186mm with optional feet)

• Overall Width: 483mm

• 4 +-10V PID or Omiga developed “Incrementer” controlled analogue outputs.

• 8 +- 200mV to +-10V Analogue Inputs providing control feedback.

• 16 24V Sinking Digital Input lines which can be configured as Generic IO, Limit Switches or Stops

• 16 24V Sourcing Digital Outputs, can be integrated directly into the test sequence as alarm notification or triggers to external devices.

• Ethernet Connection to the controller allowing remote operation

• 4.3” colour touchscreen display

• 4 closed loop control loops

• 1 KHz update rate to ensure smooth and accurate control

• 5kHz DAQ rate on analogue channels (25kHz KS/s @ 5pt averaging)

• Tuning Screen to modify PID or Incrementer gains and view the results in real time

• Automatic bump less transfer between profiles

• Create versatile sequences allowing multiple profiles to be run in a flat or multi-level looping structure.

• Create custom waveforms for use as output profiles.

• Each channel individually configurable for sensitivity

• Any channels may be assigned to any of the 4 control loops

• Adaptive feedback available for each control loop from any assigned Analogue input loop.

• Create custom profiles using a table of set points for each channel or in conjunction with custom waveforms.

• Units may be run from PC application, or configured through the colour touchscreen front panel.

• More than one unit can be daisy-chained together for harmonised operation, and run from a single PC application.

• CSV Log files, easily imported into Microsoft Excel

• Custom Log File with definable header storing up to 25 user inputs

• Generate professional multiple page reports automatically from log files

• Import Logo for created reports

• Save reports in PDF format, Microsoft Word or print directly.

• Simple analysis tools

• Multiple log in levels with customisable restricted access to all screens (specified with order)